Craftsmanship & Sustainability

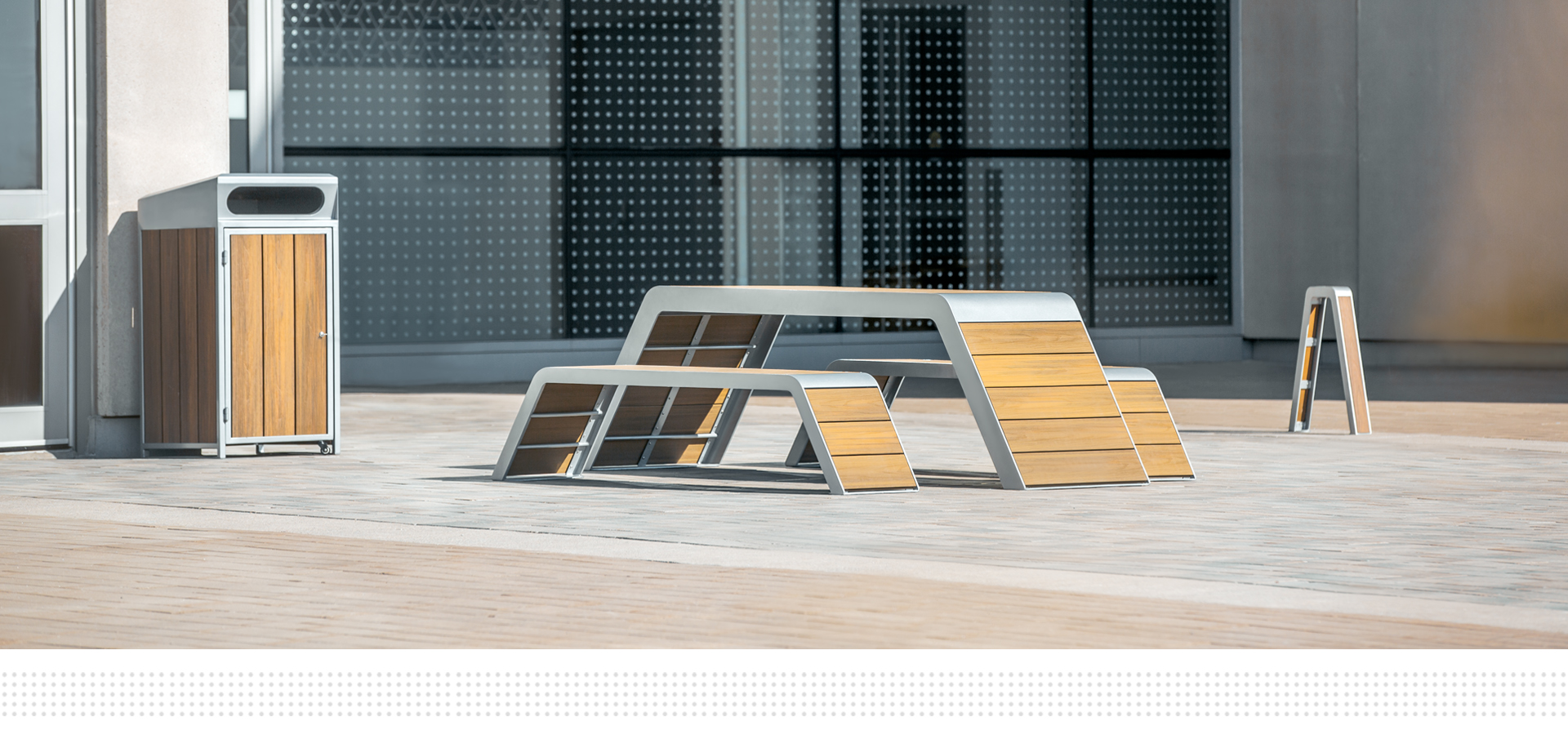

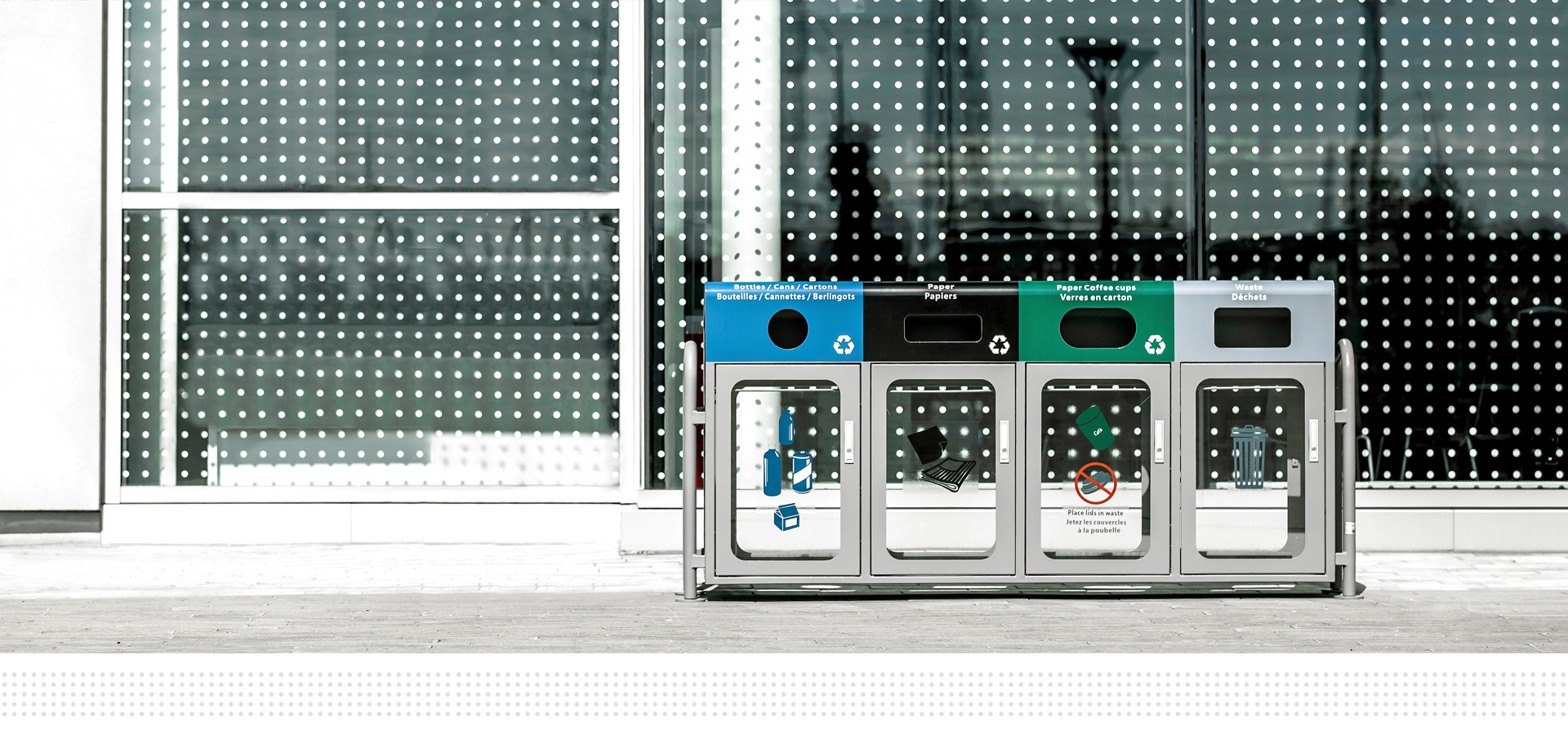

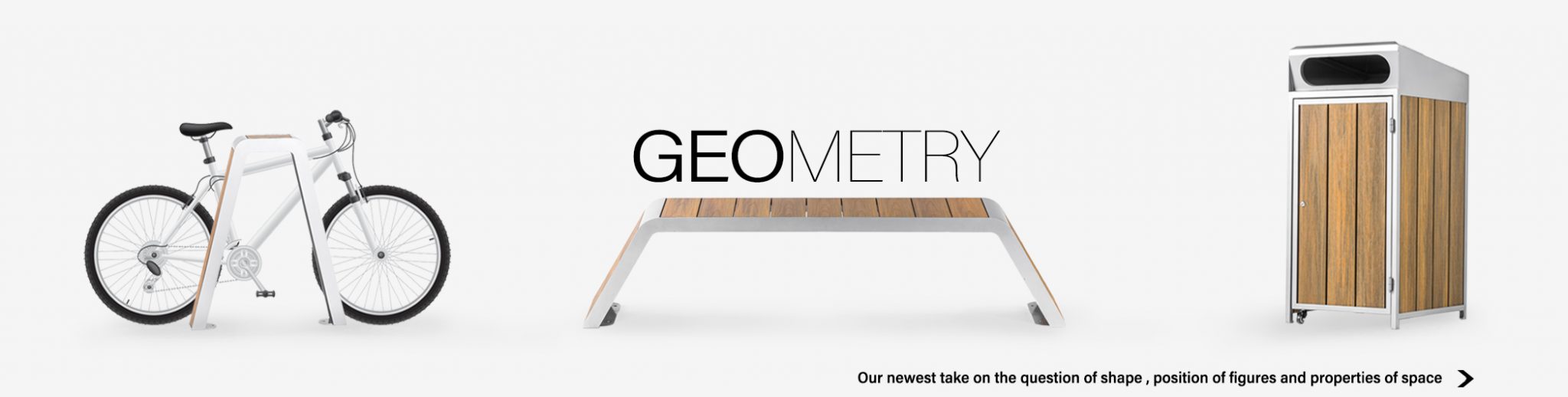

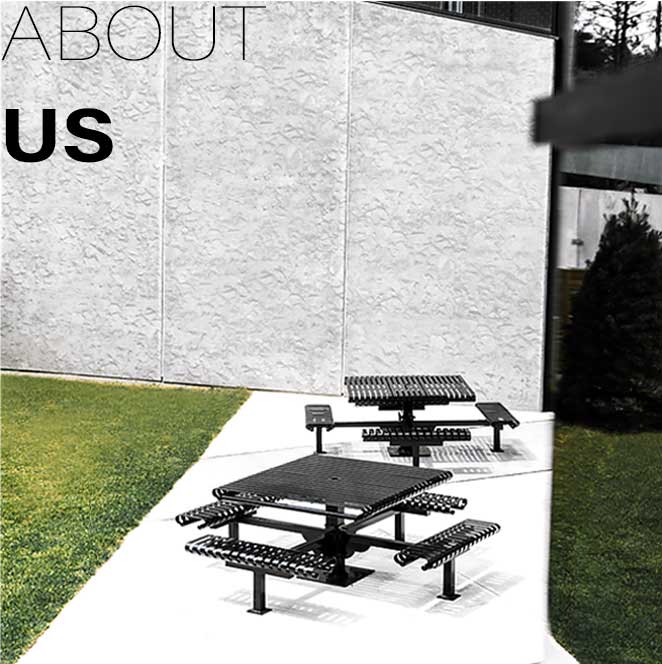

As a leading commercial outdoor furniture and commercial patio furniture provider in Canada, Canaan has been providing sustainable site furnishings (picnic tables, outdoor benches, public trash bins, recycling receptacles, planters, bike racks, bollards, and ashtrays..) and customization for commercial public spaces with exceptional customer service across North America since 2006. Integrating functionality with durability, all of our site furniture/outdoor furniture is crafted by skillful craftsmen. Inclusivity is in our design philosophy, that’s why all of our commercial furniture is available in ADA-Compliant design.

Canaan is also dedicated to reducing carbon footprints – all of our outdoor commercial furniture is produced sustainably.